After considering all different feedbacks, aspects and problem definition extracted from the research, a need for a platform (brand) that brings together sustainability, modularity and daily style through high quality wearable objects (clothing and accessories) is detected. Modularity in the majority of fashion brands on the market is focused on function rather than the aesthetics, especially for a daily usage and providing more styling options.

「 Design Question: How can the application of modular fashion serve as a medium to limit overproduction? 」

Ideation Outline

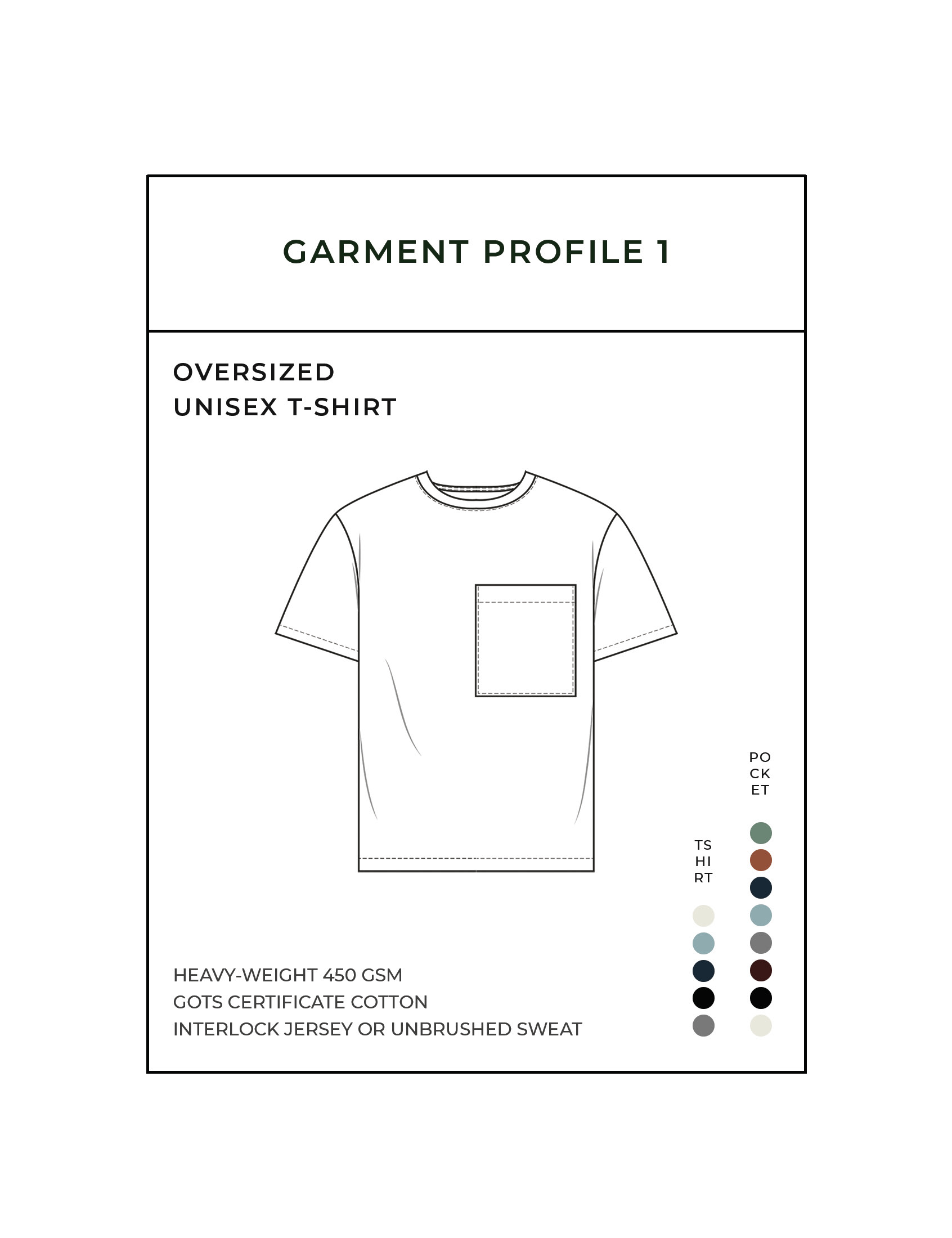

The modular clothing can satisfy different needs without buying whole new clothes. It provides the option to just purchase interchangeable elements of the garment (e.g. pocket) that users can match across the look and has a potential to activate circularity in everyone’s closet.

Finally to increase the emotional attachment and maximize the personalization of the item, the user can choose an illustration/graphic that will be embroidered on-demand on the interchangeable part. On-demand production will cut off over-production and excess inventory and is a good approach for small or even medium scale brands.

A visual comparison of several possible life cycles for apparels, and a new proposed life cycle of a modular wearable object (Circularity with single user).

Mood Board

Design Development

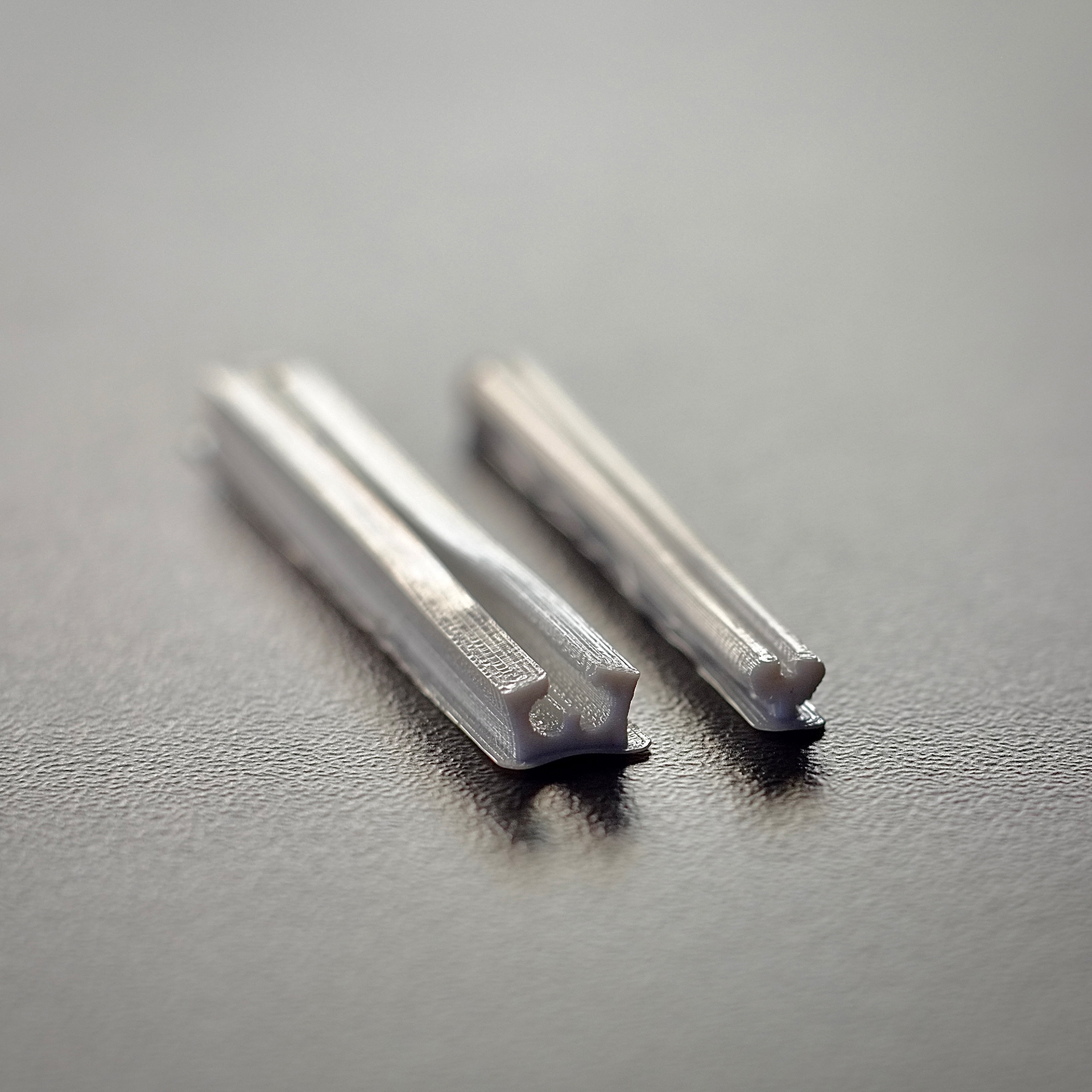

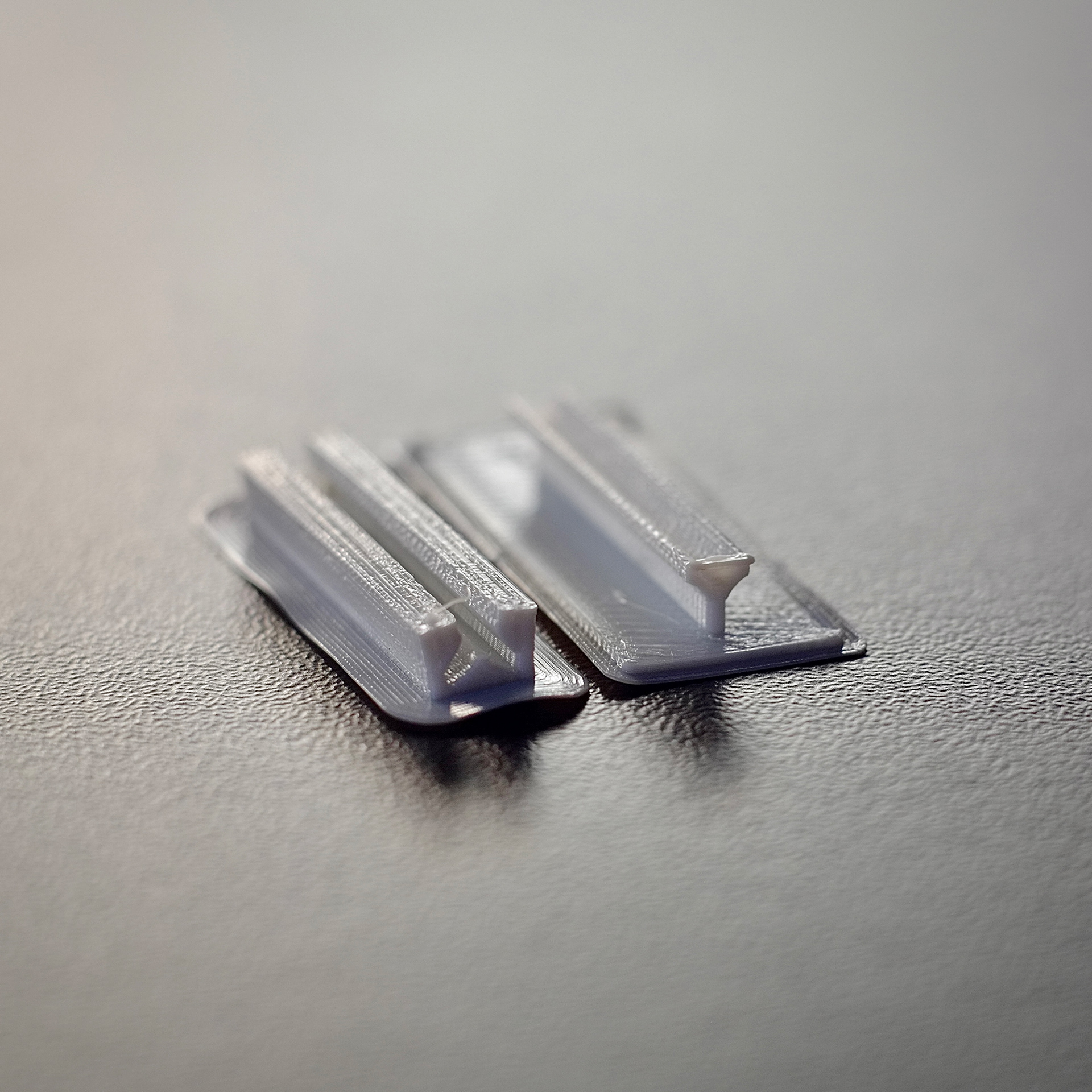

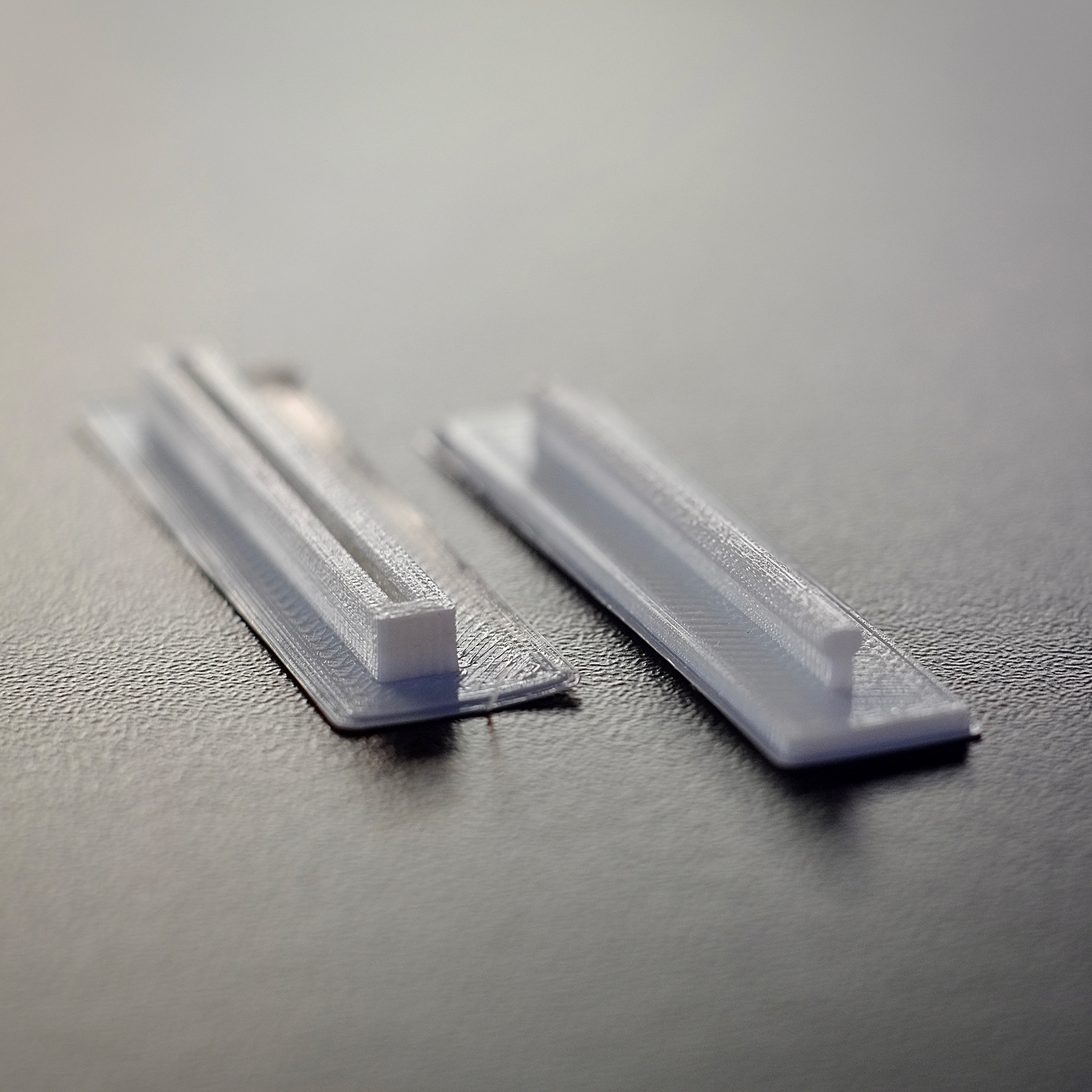

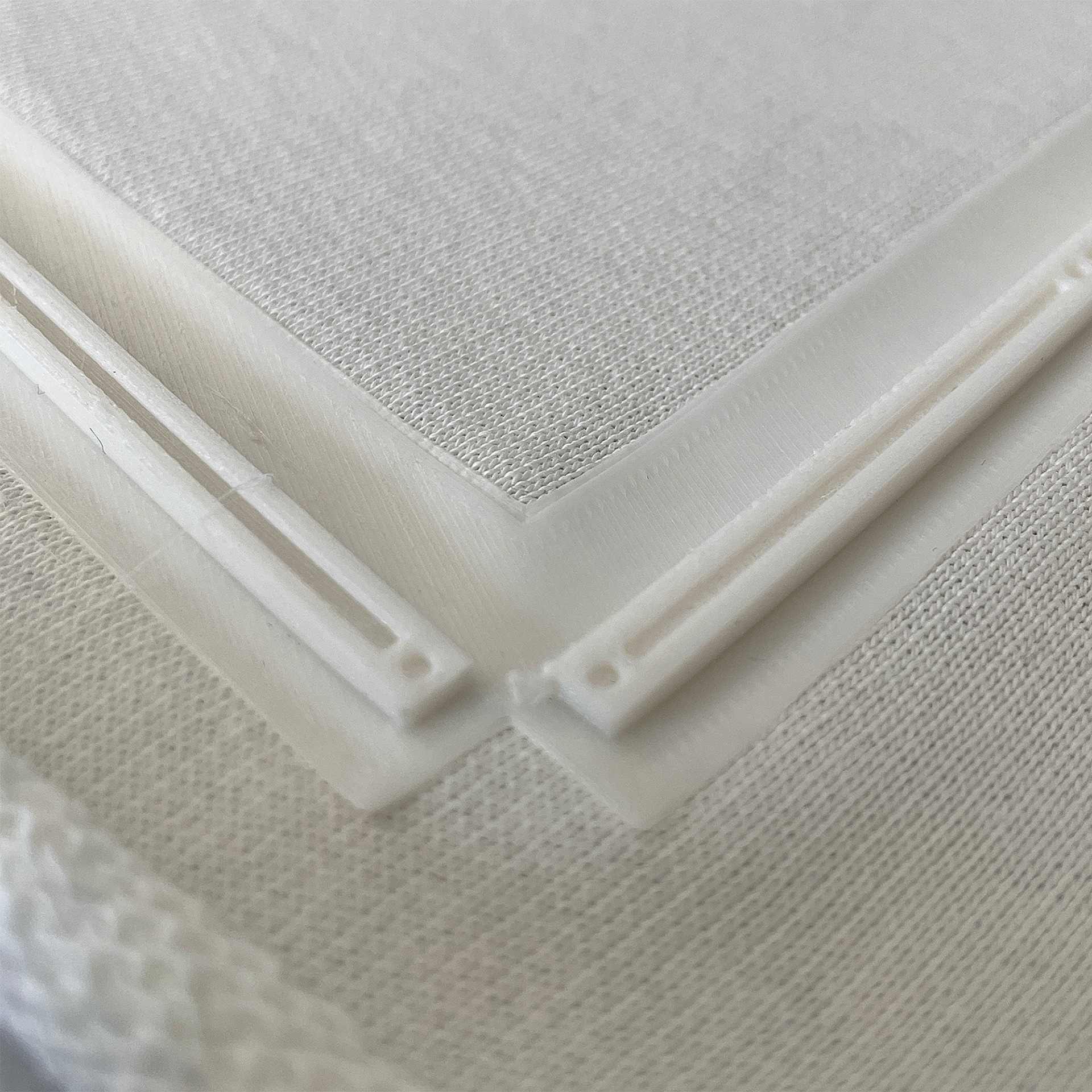

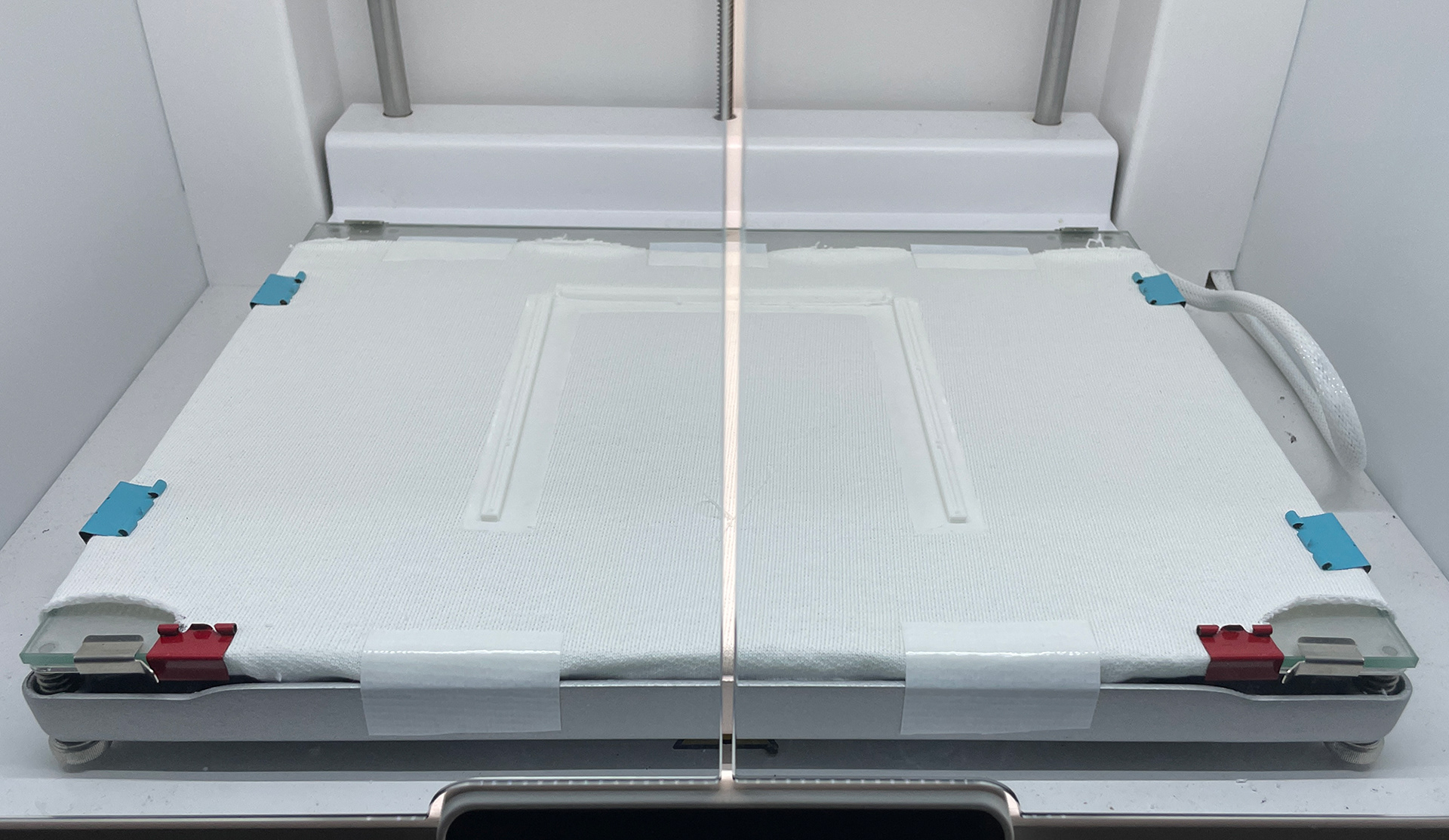

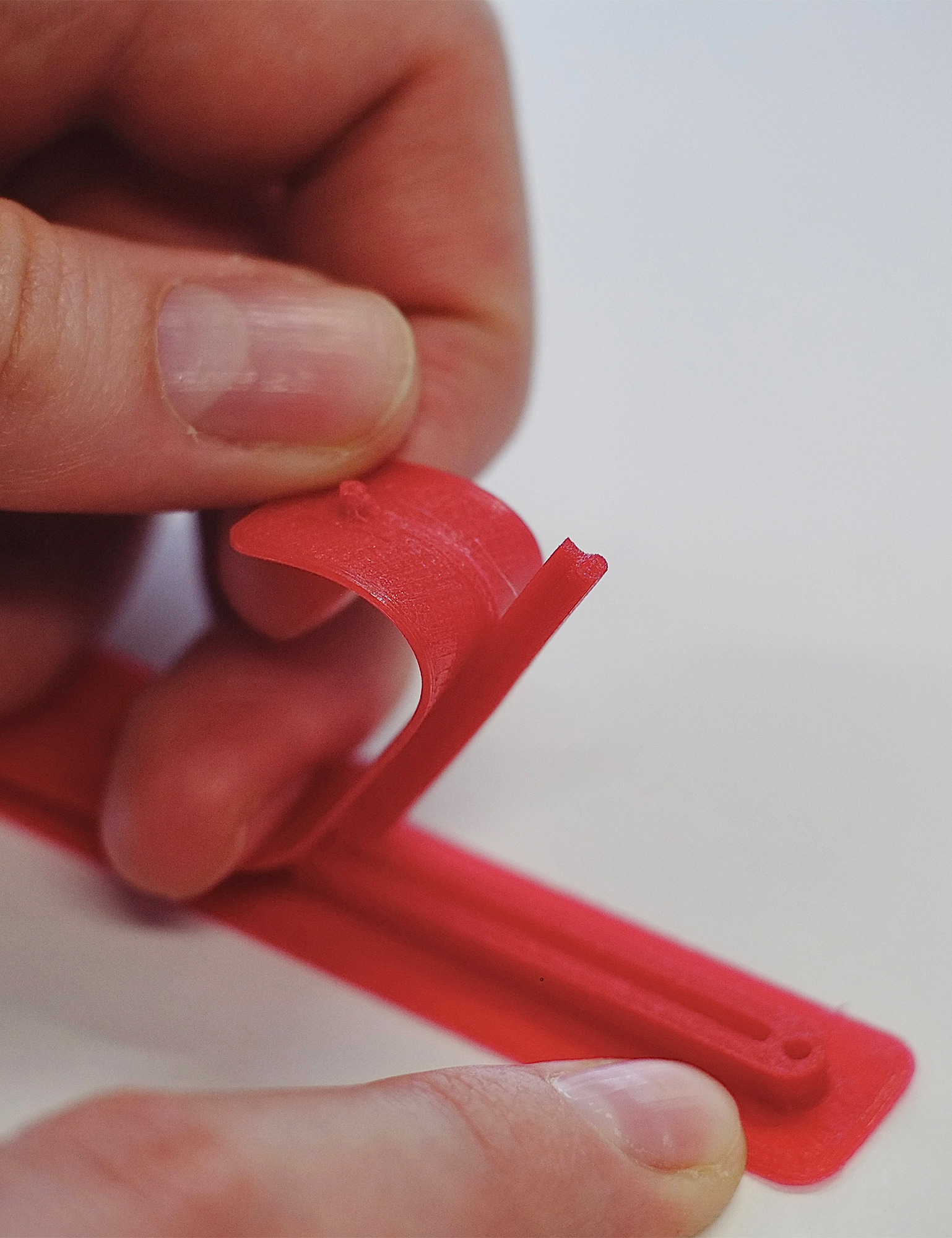

Joint/rail mechanism: To provide a functional and interchangeable pocket mechanism, various male-female joints were designed. The main challenges alongside this process was the limitation of 3d printing as a reasonable prototyping tool and various forces that a pocket should handle when interacting with human body.

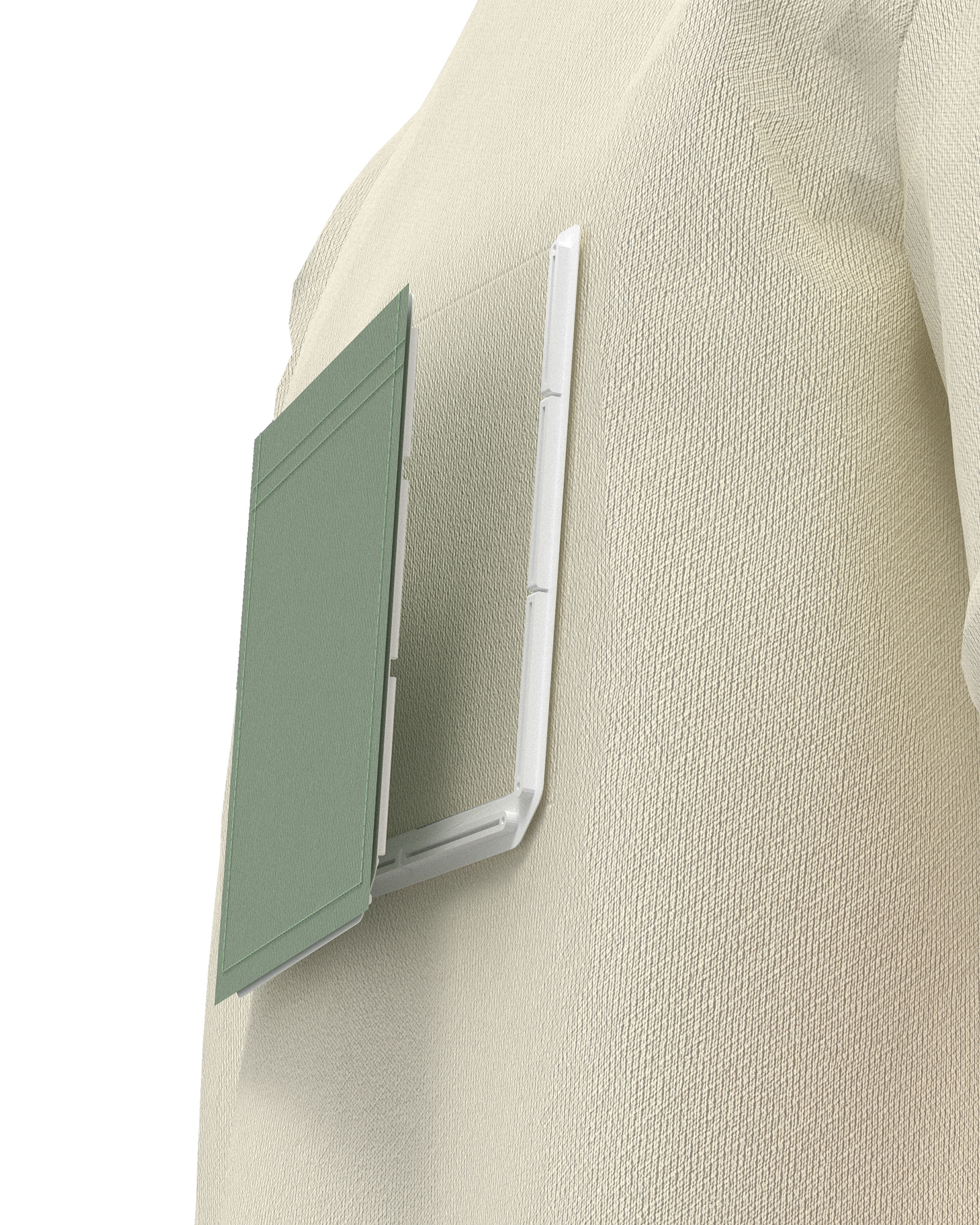

3D printing on fabric: After testing several types of joint mechanisms, the challenging adhesion test of 3d printing directly on fabric with TPU filament (Ultimaker TPU 95A) was conducted. This experiment had an eye on possibility of on-demand and partial production based on customer's orders. Even though the outcome of the experiment turned out promising, the adhesion of the printed piece on fabric is not enough to make sure it will not detach afterwards, especially with some more brutal actions like washing. On the next step, the 0.5 cm offset around the rail with a thin layer was used to stitch it to the fabric to improve the attachment and durability. This also provides the possibility to produce the rail separately even with conventional methods for large scale production, with more material options and less limitation in terms of modeling compared to 3d printing.

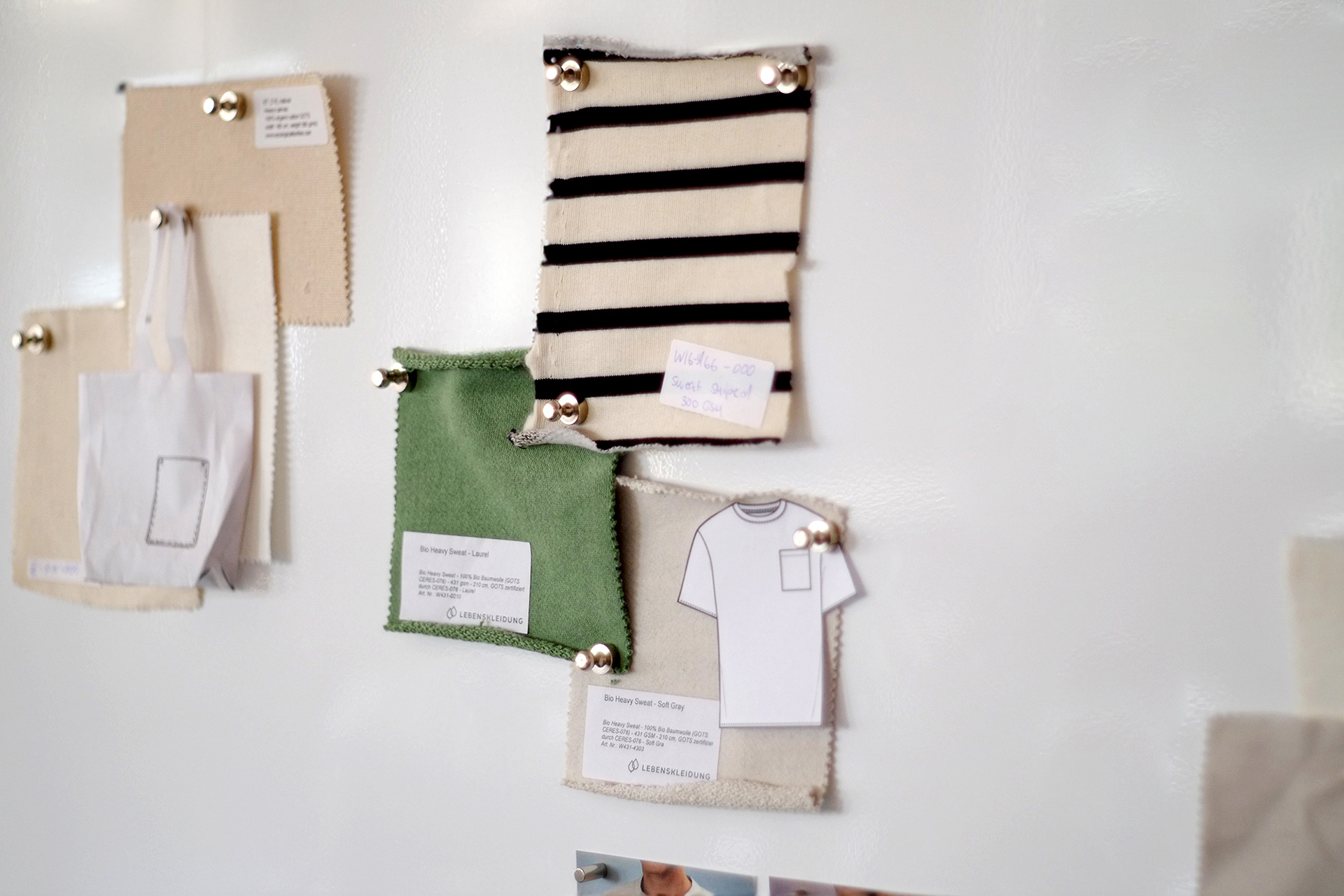

Fabric selection: As a part of research, a meeting with an organic fabric producer/shop in Berlin was set to gain more knowledge about fibre proportion in bio-based materials and know more about alternatives for normal cotton on the market. Some of these options are mentioned below:

Hemp: expensive, breathable, less common on the market, uses less water

Lyocell: man-made cellulose fibre, breathable, biodegradable, considered as polyester replacement

Certified organic cotton: uses less water, more ethical, fair working conditions

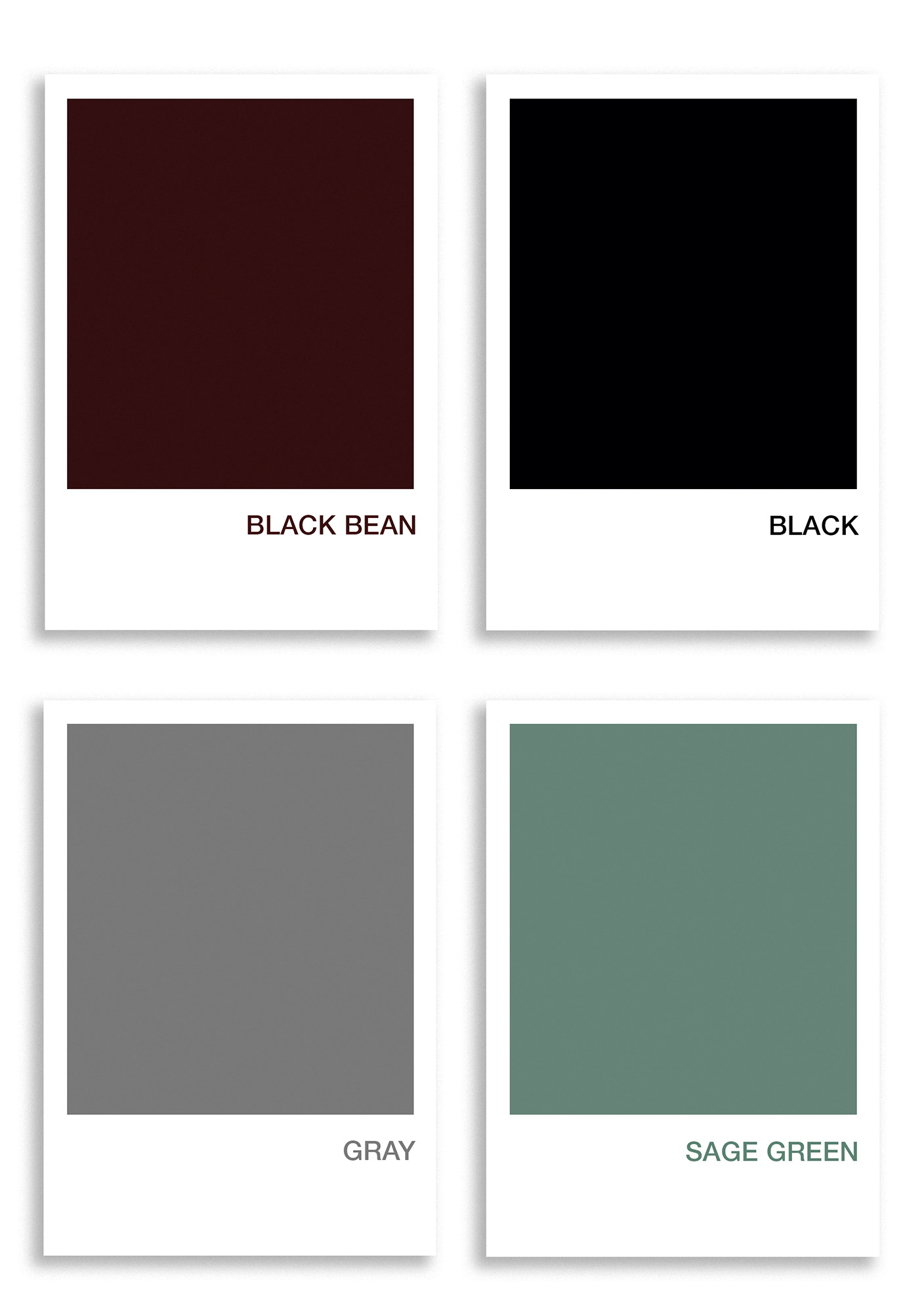

Color and Fabric Palette

Proposed color palette

Proposed color palette

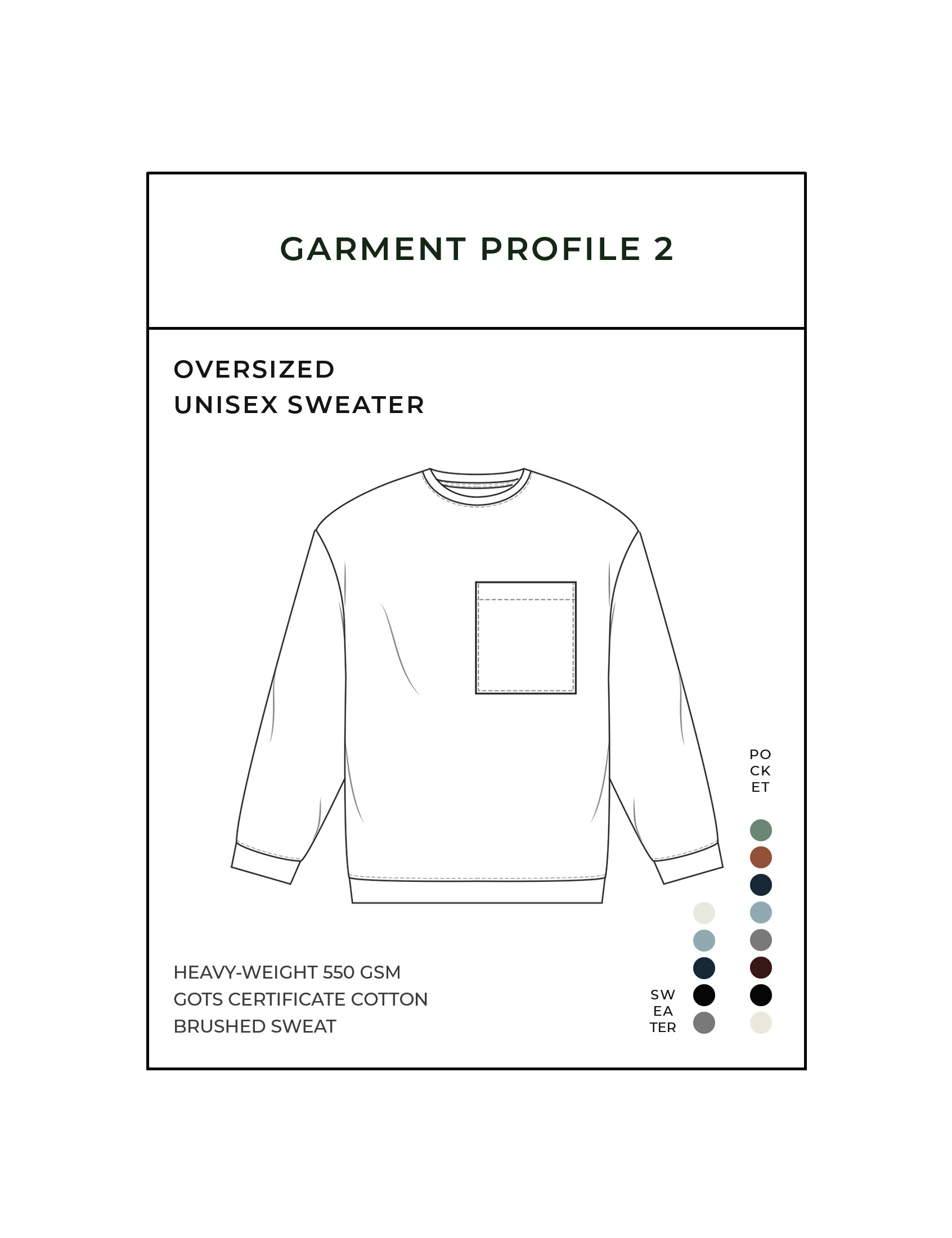

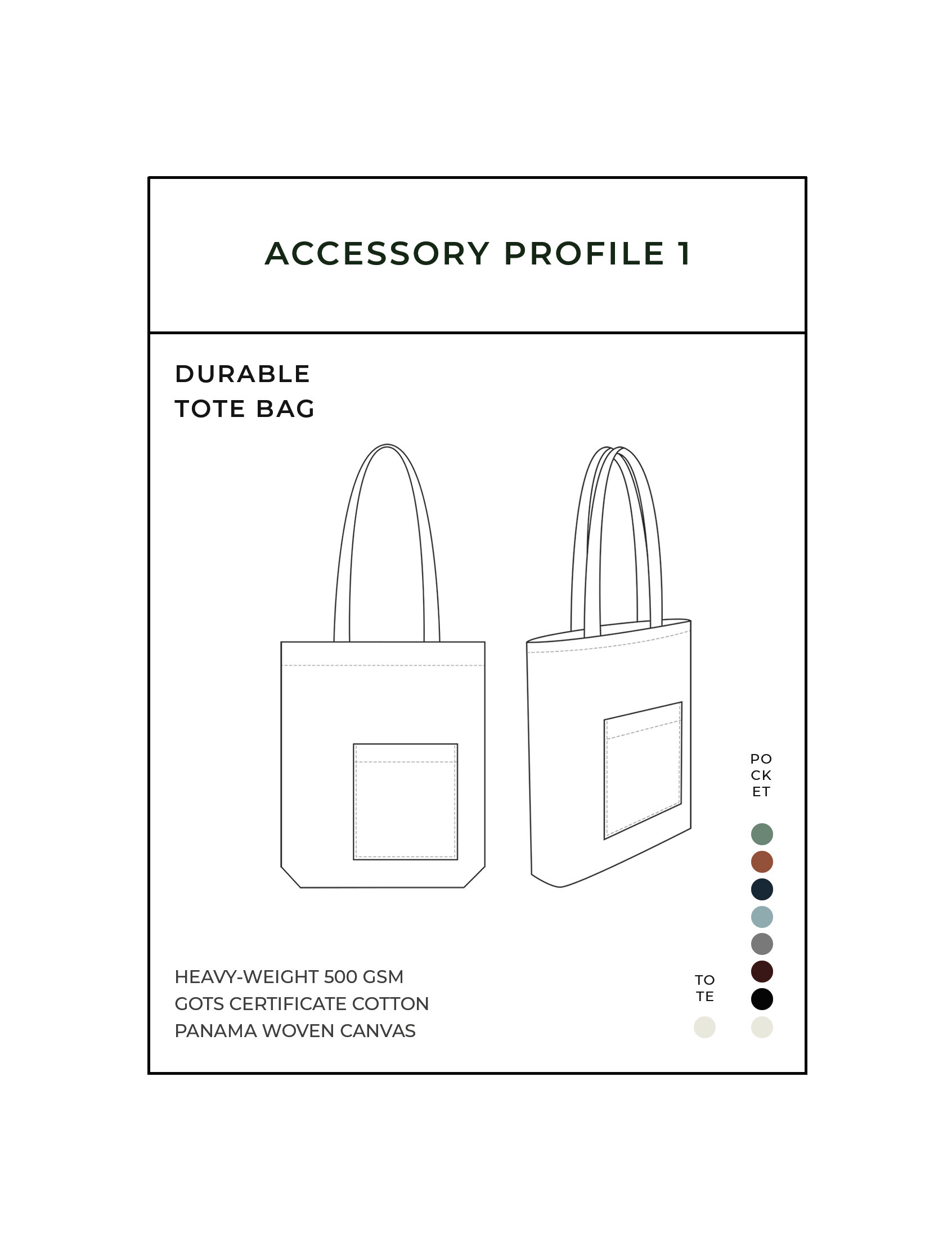

Technical Drawings

AI Generated Renders

To explore the new-existing technologies and gain a new insight on the design concept, the new Microsoft artificial intelligence tool was used to have some visual content. One of the sample descriptions was: “A heavy-weight crew neck cotton t-shirt with a loose fitting look, the t-shirt should be off-white and the pocket terracotta. The pocket can be modular and be taken off.”

AI generated renders by Microsoft designer

AI generated renders by Microsoft designer

AI generated renders by Microsoft designer

Design Contribution

For the proposed contribution (modular daily wear), the design applies the rail mechanism on pockets, turning them into interchangeable customization options. This turns it into a wearable modular item that allows for arranging various styles with the minimized use of garments and materials produced. This system can be applied on the other fashion profiles (mentioned in the design development) and make a family of products for a brand.

Attachment system of the pocket and the garment

Attachment system of the pocket and the garment

Attachment system of the pocket and the garment

Physical Prototypes

Matching the interchangeable pocket to the outfit

Matching the interchangeable pocket to the outfit

The tote bag with terracotta pocket

The tote bag with Oxford blue pocket

User Interaction

User test: choosing the matching pocket

User test: testing the mechanism

User test: trying different color options

Testing the flexibility of the rail on female model’s body

User test: testing the mechanism

Errors and defects happened with user test

Further Research

There are several actions that can be done by having access to more material options and well-equipped workshop/facilitates to improve the research contribution.

Increasing Recycling Possibilities: When it comes to recycling, complex blends always make the recycling process longer and more expensive

Ideal Fabric Selection: Possible replacements of polyester with keeping its features, finding a good blend of natural fibers with proper proportions

Ideal Joint Mechanism: Switching to conventional production methods such as injection molding provides more options of materials compared to filaments

Product Emotional Measurement: This measurement will provide a more qualitative analysis of user's emotional reactions.

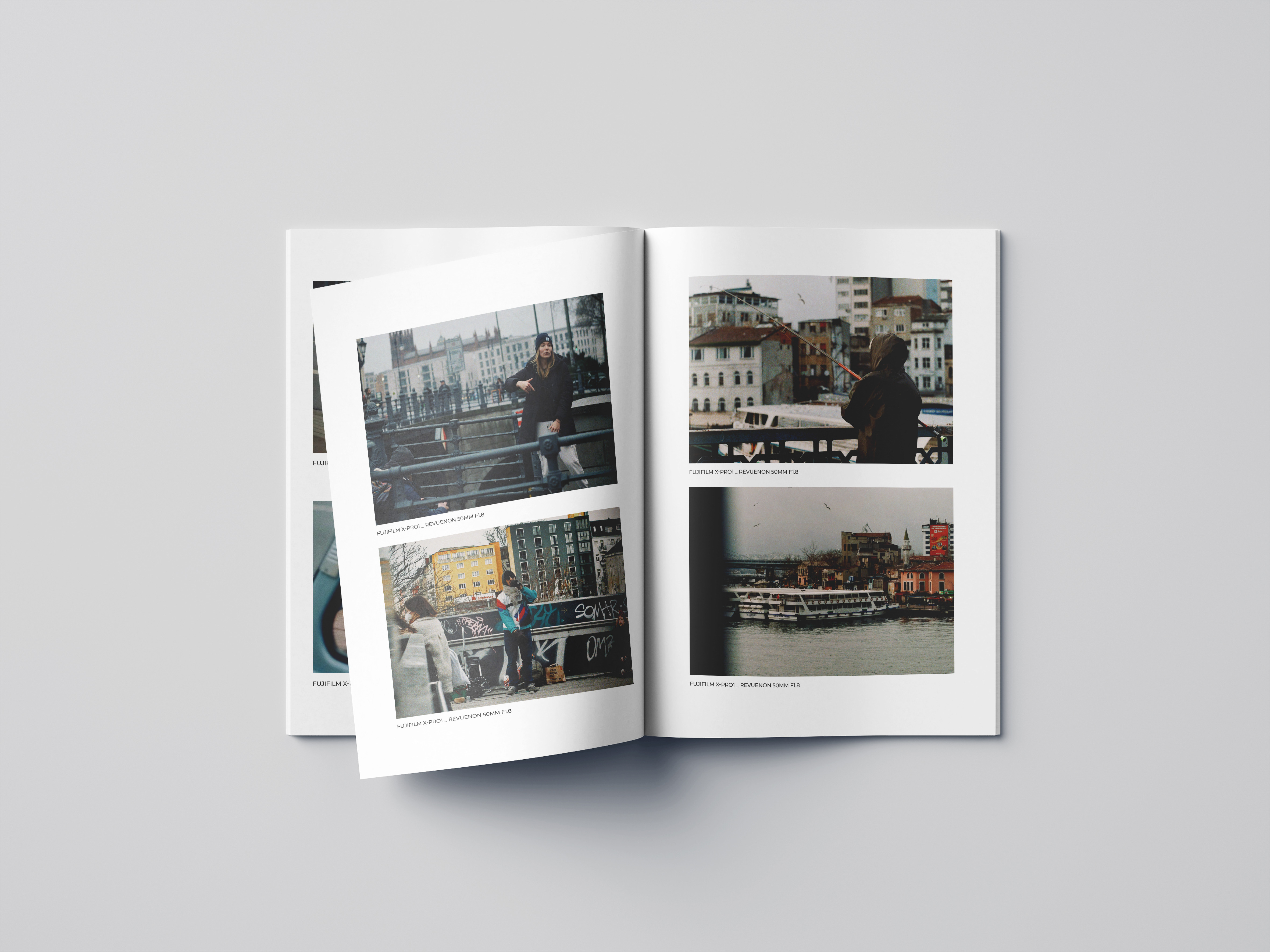

Behind The Scenes

The process of making the prototype of the tote bag

The process of making the prototype of the tote bag

The process of making the prototype of the pocket

Me, visiting an organic fabric shop in Berlin to check the materials

Assembling the tote bag

Over-locker sewing machine

〔 To check the first part of this project as "Part 1: Research & Literature Review" click on this link: Part1 〕

This is a summarized version of my master thesis I have done in 2023, for more details,

feel free to send me a message.